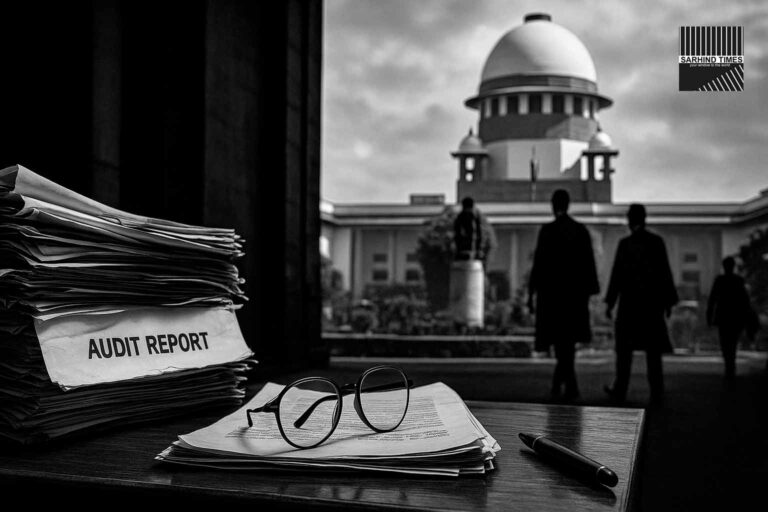

New Delhi, October 21, 2025 — SarhindTimes Bureau

In a significant policy move, the Indian government has announced that it will no longer extend the December-2024 deadline for small drug-makers to upgrade their facilities to global standards, following the tragic deaths of at least 24 children linked to contaminated cough syrups.

For decades, India has been lauded as the “Pharmacy of the World” — its low-cost manufacturing, vast generic-drug capacity and global supply-chains have made it a key pillar of global healthcare. But a series of alarming incidents has shaken that reputation and forced policymakers to act with renewed urgency. The latest trigger: the deaths of 24 children in India after ingesting cough syrup produced by a small manufacturer — an incident that follows earlier episodes of syrup-linked fatalities abroad.

The crisis unfolds

In late 2023 and in the first half of this year, multiple Indian-made cough syrups were found to contain diethylene glycol (DEG) — a toxic solvent not meant for pharmaceutical use. The fallout was particularly stark when more than 140 children died in Africa and Central Asia after consuming such syrups. India’s regulators responded by setting a staggered deadline: large pharmaceutical plants were required to meet World Health Organization (WHO)-recommended Good Manufacturing Practices (GMP) standards by June 2024, and smaller plants were given an extension until December 2024. But the recent incident involving the company — which reportedly had syrup with nearly 500 times the allowed DEG limit — has brought the issue back into sharp focus.

Government’s response

According to multiple sources, the government has refused to grant any further extension to the December cutoff. Investigations are under way, licences have been revoked (notably for the implicated company), and regulatory action is being stepped up. Officials say that public safety has taken precedence over industry pleas for leniency. The move signals a tougher posture on manufacturing compliance — especially for the sector’s “small but numerous” factories, many of which operate under cost pressure.

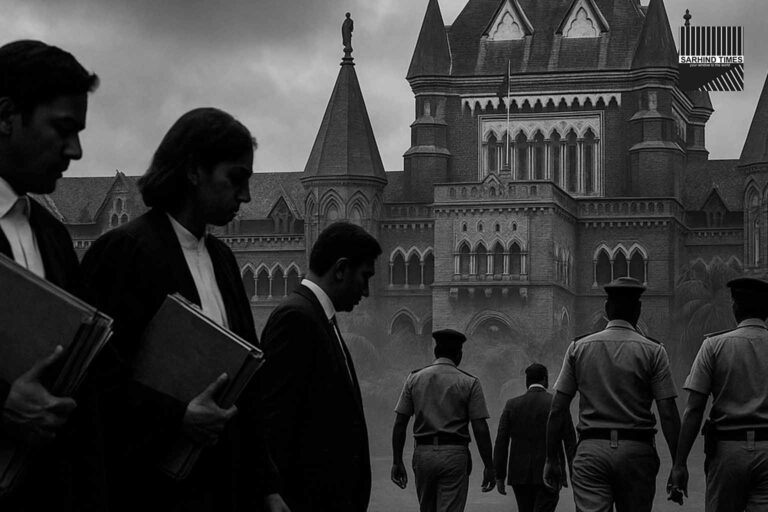

Industry push-back and fault-lines

Not surprisingly, smaller drug-makers argue that the capital investment needed to upgrade facilities is very substantial. Some warn that the requirement may push them into insolvency or shut down operations — potentially leading to supply disruptions, especially in the domestic generic market. Industry lobbyists had hoped for a phased extension or a tiered approach, but the regulatory stand suggests otherwise. Analysts believe a shake-out is likely: smaller, non-compliant firms may be forced to merge, consolidate, or exit.

Yet the counter-argument is clear: India’s drug reputation suffers when safety incidents surface, and trust — both domestic and international — is fragile. For a country exporting generics and active pharmaceutical ingredients (APIs) globally, a single major scandal can jeopardize large contracts and regulatory approvals in overseas markets.

Global credibility at stake

India’s role as a global supplier of affordable medicines rests on the credibility of its regulatory and manufacturing ecosystem. Repeated incidents of contamination, sub-standard manufacturing, or weak oversight are cast as systemic risks by buyers, especially in developed markets. Regulator groups and compliance firms note that while the large Indian pharma players have invested heavily and upgraded capacity, the “long tail” of smaller facilities remains a vulnerability.

The recent cough-syrup‐linked deaths have sent ripples overseas: importers in several African countries have tightened scrutiny of Indian suppliers, and international media have questioned whether India is losing touch with the “world-class” compliance narrative it once championed.

What the upgrades involve

Meeting WHO-GMP standards is no small feat. Key elements include: ensuring clean-room manufacturing; controlling cross-contamination (especially when solvents or APIs are involved); rigorous batch testing and documentation; robust traceability; and frequent audits. Many small units have legacy equipment, weaker quality management systems, and limited investment capacity — making compliance both technically and financially demanding.

Government agencies now plan more frequent inspections, random batch testing, and possibly a public database of compliant manufacturers. The message is clear: “no more gentle hand-holding”. Regulatory insiders say that the seriousness of issuing a December deadline — and then refusing extension — reflects a turning point in policy tone.

Supply-chain & cost implications

There is a realistic risk that some generics may see short-term supply disruption. Smaller players unable or unwilling to upgrade may shut down or merge, reducing the number of active suppliers. This, in turn, could drive up costs domestically (for generics) and impact export pricing. The government has to balance safety imperatives with supply affordability.

In addition, global buyers increasingly demand transparency, digital traceability and audit-friendly systems — all of which may further raise cost bases for Indian manufacturers. Brand owners, contract-manufacturers and export-oriented units will need to factor in higher capex and compliance cost over the next 2-3 years.

What this means for patients

For Indian patients, the government has assured that adequate alternative supply will be maintained and major pharmaceutical companies have the capacity to fill any shortfall. However, this will require proactive monitoring of essential-drug lists and possible buffer stocks. Critics say the government must ensure there’s no disruption to access in remote or low-income areas, where generics play a vital role.

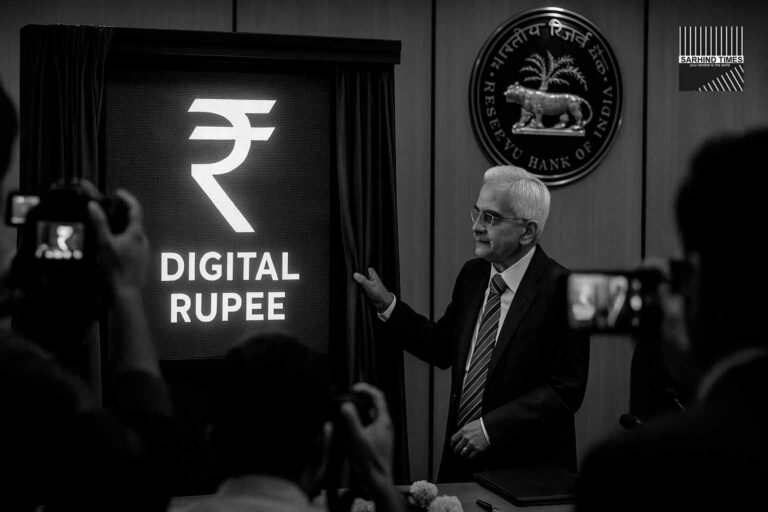

Strategic and reputational impact

Viewed broadly, the policy surge signals a shift: India is no longer content with “volume at any cost” in generics; regulatory integrity and global trust are now higher priorities. The country’s ambition to remain a global pharmaceutical hub depends increasingly on compliance, governance and data-driven oversight, rather than just scale and cost-competitiveness.

For policymakers, the stakes are high: a clean record will support Indian firms aiming for regulated-market approval, entry into specialised biologics and high-end APIs. A tarnished image would invite tariff or non-tariff barriers, loss of market access and reputational damage.

Voices from the field

“We cannot compromise on safety; every child’s life matters,” said a senior health-ministry official reacting to the latest incident. Meanwhile, a spokesperson for the industry association said: “The deadline is tight and the investment heavy — we urge the government to consider transitional support for smaller units.” Analysts say the “great-reset” period is here — smaller units must adapt or exit.

Looking ahead

Key things to watch: Will a public list of certified plants be published? Will the government introduce financial or tax incentives for upgrades? Will export markets reward compliant Indian units with faster approvals? And will quality-track record-improvement become a competitive differentiator for Indian pharma? The next 12 to 24 months will be pivotal.

Conclusion

India’s pharmaceutical sector stands at a crossroads: balancing its cost-led global leadership with a reinvigorated focus on safety, compliance and reputation. If the upgrade drive succeeds, India could emerge even stronger in the generics and API space. If not, disruptions and credibility loss could follow. From tragedy has come urgency — and the sector is being reset.

#PharmaIndia #GMP #DrugSafety #Generics #HealthcarePolicy #IndiaExports #Manufacturing #HealthNews

+ There are no comments

Add yours