New Delhi, October 17, 2025 — The Indian government has decisively refused pleas from pharmaceutical companies to extend the December 2025 deadline by which all drug manufacturing plants must conform to global Good Manufacturing Practice (GMP) norms. The refusal comes amid growing public anger and sorrow over recent deaths of children who consumed contaminated cough syrup. In effect, the deadline now stands as a red line: compliance or repercussions.

This moment marks a turning point in India’s pharmaceutical regulation, where industrial anxieties and public safety imperatives collide. Smaller and mid-tier firms, many of which had sought relief, now face distinct pressure to retrofit, revamp, or exit.

The Crisis That Catalyzed It

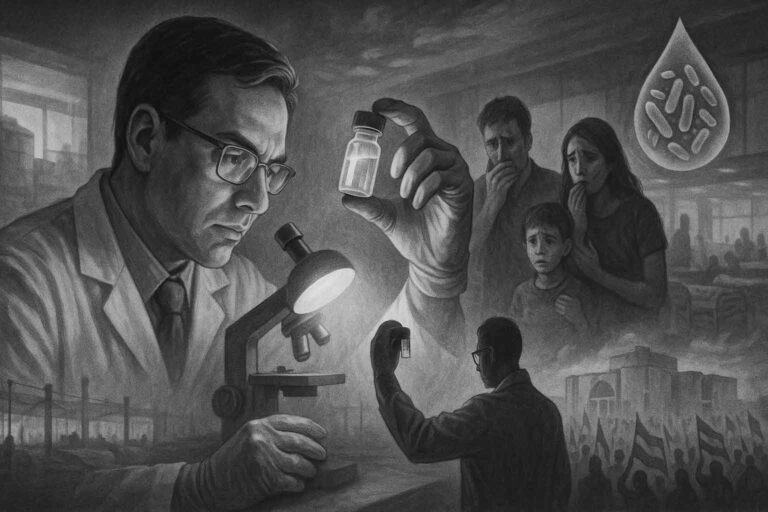

The backdrop is grim. Earlier in October, reports emerged of 24 child deaths linked to Coldrif, a cough syrup made by Sresan Pharmaceuticals. The syrup was found to contain diethylene glycol (DEG) at levels close to 48.6 % — nearly 500 times the permissible limit.

Historically, India has faced stains on its pharmaceutical reputation: decades back, syrups contaminated with DEG caused child deaths in Africa and Central Asia. In response, in late 2023, the government mandated stricter rostered testing and plant upgrades to global standards. Many leading players complied early; smaller firms were given staggered timelines.

Now, in rejecting extension requests, the government says it cannot allow “people dying” to become the impetus for inaction.

What the Government Decision Entails

No More Extensions

Drugmakers had asked for further breathing room, citing capital constraints and supply disruption risk. But the government stood firm: this is the last deadline.

Enforcement and Audits Tighten

Licenses will be revoked, plants shut, and inspections intensified. Already, the license of Sresan has been revoked and its plant operations suspended.

Penalties and Accountability

Compact firms and large ones alike will be held to account. Non-compliance could attract severe regulatory, administrative, and criminal consequences.

Phased Exit of Export Testing Rule

After all plants comply with GMP, the extra government testing for cough syrup exports (a rule introduced in 2023) may be phased out.

Industry Reactions & Fear of Fallout

Leaders of the smaller pharmaceutical units warn of closures, layoffs, and supply shortfalls. The SME Pharma Industries Confederation asserted that nearly half of certain manufacturing units—especially in states like Himachal Pradesh—might shut if no relief is granted.

Some firms have already discontinued certain product lines citing unaffordability of upgrades. However, senior government sources say that major drugmakers—those with more resources—are expected to pick up slack in production if smaller players shrink.

Observers point out that India’s pharmaceutical industry is heavily skewed: a handful of large firms produce the bulk of drugs, whereas thousands of smaller units cover the remainder. The disruption risk lies in this fragmentation.

Regulatory & Public Health Context

Past Warnings & Lapses

In October, the WHO issued alerts over contaminated Indian cough syrups, flagging “regulatory gaps” in how locally sold medicines are screened.

Investigations revealed certain firms failed to test every batch as mandated.

Meanwhile, U.S. FDA confirmed that the toxic syrups had not been shipped to America, reducing international trade liability but not domestic risk.

Local Crackdowns

State governments and drug controllers have ordered seizures, halted sales, and increased surveillance. For example, Gujarat authorities flagged problems in two other cough-syrup manufacturers (Respifresh, ReLife) and directed suspension until compliance is assured.

Tamil Nadu revoked Sresan’s licenses, ordering full shutdown.

Political & Trust Risks

India’s image as the “pharmacy of the world” now faces fresh credibility pressures, especially as the world watches for quality consistency.

Public trust in medicines could erode, and efforts to export drugs may suffer if international buyers perceive systemic weakness.

Implementation Challenges: What Firms Need to Do

To comply, many companies must:

- Reengineer facilities (sterilization lines, cross-contamination controls)

- Upgrade instrumentation, validation & calibration systems

- Install strict sampling, batch-traceability and testing regimes

- Enhance staff training, process documentation, QC/QA systems

- Thermal, environmental, and cross-flow control infrastructure

- Possibly shut down portions temporarily for retrofits

Smaller units, especially with thin margins or debt loads, face severe funding stress, leading some to consider exit. Meanwhile, supply chain disruptions or delayed upstream inputs may cause intermittent product shortages in the short run.

Risks, Implications & Bullets to Watch

- Supply crunches: Some cough syrups or related formulations may face short-term shortages

- Price pressures: Retail pricing may rise if input, compliance or capital costs spike

- Mergers / consolidations: Smaller firms may sell, exit, or be absorbed by larger groups

- Stricter licensing regime across other drug categories

- Global buyer caution: Export markets may require extra diligence or audits

- Litigation & liability: Families affected may file civil or criminal suits, increasing risk exposure

- Policy clarity needed: Ministry and regulators must issue detailed operational guidance, transitional roadmaps

Case Study: Sresan & Coldrif – What Went Wrong

- The batch SR-13 of Coldrif (manufactured May 2025) was found to contain 48.6 % DEG, far exceeding the limit.

- Authorities say the plant had not upgraded earlier despite mandates.

- License revocation followed; owner arrested.

- Money-laundering and regulatory raids are underway across multiple sites tied to Sresan.

- Local investigations in Madhya Pradesh show that victims like Mayank Suryavanshi had been prescribed Coldrif; doctors are also facing manslaughter probes.

The failure in Sresan’s case became the tipping point for the government’s stricter stance.

Voices & Reactions

“The deadline cannot be extended again and again — people are dying,” said a government source explaining the refusal.

Industry groups have countered:

“Extension is needed — many small firms will collapse, jobs will be lost, the overall medicine ecosystem could suffer.” (Leaders from SME Pharma groups)

Consumer rights advocates and medical ethics specialists applaud the firmness:

“Patient safety is non-negotiable—regulation must act decisively.”

The Road Ahead: What to Monitor

- Regulatory clarifications: Rules, timelines, grace periods, inspection protocols

- Transition assistance: Subsidies, loan guarantees, technical support for smaller units

- Supply timelines: Which formulations or dosages are likely to be disrupted

- Enforcement actions: Number of plants shut, prosecutions, license cancellations

- Export market response: Will global buyers demand additional audits?

- Public trust metrics: Consumer sentiment, trust in generics, fallback to branded imports

Conclusion

By refusing to delay the upgrade timetable, the Indian government is sending a strong signal: quality and safety take precedence over convenience or industry pressure. The decision acknowledges painful short-term consequences—factory shutdowns, supply stress, economic hardship—but positions India on a sterner regulatory trajectory.

The risk is real: if execution falters, firms may struggle, and public access to essential medicines may be compromised. But inaction carries a heavier moral, health and credibility cost. For India to remain a global pharmaceutical power, it must prove that its products are not just affordable—but safe, reliable, and world-class. #Pharma #DrugSafety #GMP #Healthcare #Policy #MakeInIndia #PublicHealth #Regulation

+ There are no comments

Add yours